Hot runner feeding method 1: "point gate", the point gate method is the most common feeding method, which is determined by several factors such as gate size, gate cooling and tip temperature, etc., it is suitable for almost all known plastics, and its gluing mouth will leave a small gate mark on the surface of the product, and its size is determined by the size of the gate and different plastics.

Hot runner gluing method 2: "big nozzle", the big nozzle is an open hot nozzle, which will leave a small part of the handle on the surface of the injection molding product, which can provide a large gate size, achieve excellent pressure holding effect to reduce the product stress, and can be applied to the gate mark requirements are not high or the split channel gluing method.

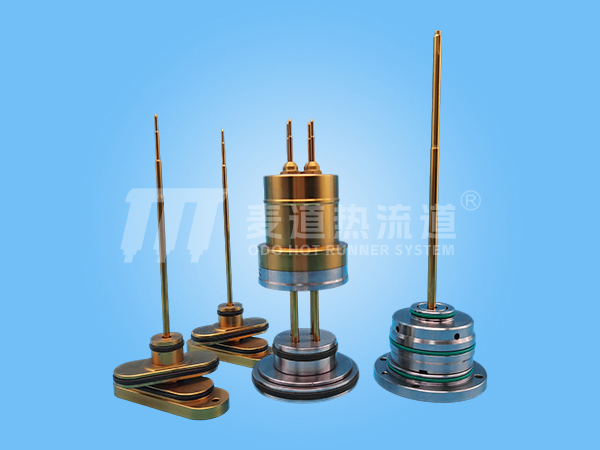

Hot runner feeding method 3: "needle valve type", for the needle valve type, the valve needle is controlled by mechanical pneumatic or hydraulic, the valve needle will close the gate at the end of the pressure holding section, that is to say, when the product is not fully condensed, the glue feeding system has been closed, which can shorten the forming cycle. The needle valve type can achieve no gate marks, and only leave a circle of marks on the surface of the product or not, which is the best solution for strict surface requirements.