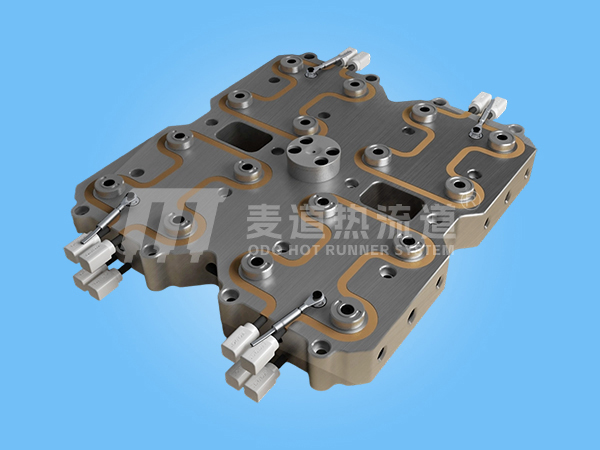

The shunt plate is mainly composed of three parts, heating system, temperature sensing system, and flow channel system.

The heater has two ways, one heating rod conduction, the second heating rod conduction. For now, it is still the mainstream heating rod structure, and the main Taiwanese brands of the original heating rod are mostly. The arrangement of heating rod is absolutely a knowledge, for the multi-cavity system, the arrangement of heating wire has a great effect on the balance; At the same time, the arrangement of symmetrical plastic products also requires heating rod symmetry; At the same time, it leads to a heating density concept (the total heating power of the shunt plate/the volume of the shunt plate), which may not be very important for conventional materials, but must be considered for crystalline materials.

The temperature sensing system currently has several main streams, one is the surface probe, the other is the internal probe, in fact, this is through the temperature sensing line to measure the actual temperature near the gate of the shunt plate, and the conventional setting is in the position of high heating density. However, for temperature-sensitive materials such as PVC and POM, it is recommended to minimize the length of the heater and measure the temperature in multiple areas.

In addition to the above two components, the runner system is still very important. First, the material of the diverter plate, currently mainly stainless steel and P20, but for special materials or need special steel (halogen-free materials, PVC materials, etc.), the flow path generally forms the main gun drilling processing, and the other is welding processing, due to cost and technical reasons, the mainstream is gun drilling, special applications (balance requirements, color requirements, anti-corrosion requirements) to consider welding; Second, the diameter of the runner, for different fields of products, the mold structure is completely different, so the hot runner runner is not the same, the packaging medical industry requires balance, color change; The automotive industry requires color changing and sequence control; Headlights require low pressure loss; Low pressure injection molding requires a small pressure (less than 40MPa is recommended), in short, in short, the flow diameter is selected according to the product technology application.

For the shard plate processing, the plug structure is more critical, there are welded on, there are interference fit, there are screws blocked, all are large and small, there are also the same diameter plug flow channel, so many dead corners are generated in this position. The thickness of the diverter plate is related to the diameter of the runner, but it is also related to the quality of the steel (international brands choose one hundred, etc., and the ordinary material is domestic). For processing, the Angle between the flow path and the flow path of the diverter plate is ensured to be above 60 degrees.

In fact, the processing of the shunt plate basically determines the positioning of the product and the design capability. So it's a Slam Dunk.